Mining Division

Prisma Tyres Mining Division is there not only to supply tyres but specially to grant a complete technical consulting in order to minimize as much as possible the annual costs and maximize tyres' life with consequent increase of the productivity.

Thanks to the professional experience of our technicians, gained in more than 35 years in the mining field on behalf of the top manufacturers, we are able to provide innovative services and solutions to cut down as much as possible the costs. This factor became lately of very high importance since nowadays the annual cost for tyres in a mine can affect up to 30% of the total costs.

Our services

-

Staff's training and education

Upon client’s request our team is organized and available to give courses to educate and form the staff directly on site. The main topics that are dealt with are relevant to a correct maintenance and therefore a longer lasting of the tyre avoiding unnecessary and additional costs.

Theoretical and practical training on:

- Assembling and disassembling tyres from 24 to 63 inches

- Problems relevant to pressure

- Tyre inflation by air or nitrogen

- Dumpers monitoring system

- Equipment

57" tyre assembling training.

57" tyre assembling training.

Quajone. Peru 45" tyre disassembling training.

45" tyre disassembling training.

Massa Carrara. ItalyTheoretical courses for drivers, operators and staff:

- General information on the tyre

- Problems relevant to tracks

- Loading and unloading points

- The importance of TKPH (to learn more please click here)

Definition: Ton kilometer per hour (TKPH) is the measurement of the work load of a tyre and is based on the weight and speed that the tyre can handle without overheating and causing it to deteriorate prematurely. A TKPH rating for a tyre is the theoretical maximum workload it can take (average weight on the tyre * average speed of the truck OR more specifically, tons * km/h).

Example: On one axle, the truck has two tyres. The total load on the axle is 100 tons when the truck is loaded and 50 tons when the truck is empty. The average load on the axle is 75 tons that is 37.5 tons per tyre. If the average speed of the truck is 20km/h, the tyre rating would need to be 37.5*20 or 750 TKPH to avoid being a limiting factor.

How TKPH affects haulage in Spry: TKPH is calculated per schedule step. If the calculated TKPH is higher than the tyre’s rating, TKPH becomes a limiting factor. This will result in the Adjusted Cycle Time being increased until TKPH is equal to the Tyre Rating.

- Safety in the work sphere

Training course.

Training course.

Alumbrera. Argentina Service center.

Service center.

Rio de Janeiro. Brasil -

Tyres supply

-

Tyres repair

In those sectors where you operate on rough terrain it is unfortunately quite easy that the tyres suffer substantial damages with an unavoidable machine downtime that generates delays in work in progress and consequential economic losses. PT can supply you either with the perfect know-how, to repair the tyres on site that underwent damages, or the relevant training of the staff.

Damages to be repaired:

- Examination of the wounds/damages on the tyre

- Tyre structure (radial/cross ply)

- How to repair on bead, side and tread

- Choice of the tools suitable to repair

- Choice of the product to be used to repair

- Vulcanisation method: we can supply you with different methods of vulcanisation according to the type of the damage

- Check before and after reparation

- Safety in the work site

Bead

Bead Tread

Tread Side

Side -

Tyres retreading

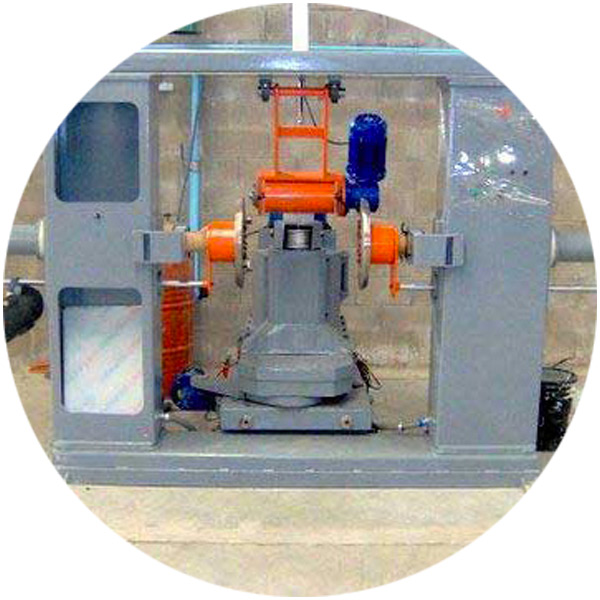

PT is able to supply and install, wherever considered to be convenient, turnkey retreading systems directly on site complete with the related after sale assistance.

Here to follow the points that will be taken into consideration by our technicians:

Tyre retreading with wheel rim size from 24 to 63 inches

- Tyre structure (radial/cross ply)

- Examination of the tyre damages

- Training on the retreading equipment

- How to repair on bead, side, tread

- Control of the vulcanisation with and without thermocouples

- Check before and after retreading

- Safety in the workshop

Tyre retreading with wheel rim size from 15 to 24.5 inches

- Tyre structure (radial/cross ply)

- Examination of the tyre damages

- Training on the retreading equipment

- How to repair on bead, side, tread

- Control of the vulcanisation with and without thermocouples

- Check before and after retreading

- Safety in the workshop

-

Tyres recycling

Since long, a matter of primary importance is the safeguard of the ecosystem that is essential in order not to modify the delicate balance of our planet.

Tyres, if not correctly disposed, can be the cause of a high level of environmental pollution.

PT is able to supply, thanks to partnerships with the most qualified companies in this field, turnkey recycling plants to correctly dispose tires that reached the end of their life cycle.

Thanks to modern technologies all disposed tires can today be transformed in:

- Dust

- Crumb rubber to produce energy

- Paving tiles

- Acoustic panels

- Recovery and sale of the metal parts

- Textile recovery to produce energy

- Cracking: diesel/energy